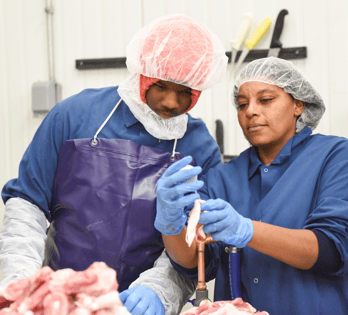

Lisa Brown, our Poultry Plant Manager, has worked at White Oak Pastures since 2012. Next month will mark her sixth year with us. Learn more about Lisa, our Manager of the Month.

“I started in the poultry plant on the bottom of the line plucking feathers. I then worked my way up to the viscera table, where I worked for two years. I was introduced to the Hazard Analysis and Critical Control Point (HACCP) books and started working with the HACCP program and the line. HACCP are the rules and guidelines that you follow to work under the United States Department of Agriculture. I started learning that, along with other office responsibilities until there was a management position available. I went for it, and got it!

I came here for a change of scenery. I was at my other job with Birdsong Peanuts for five years in Blakely, GA. Things weren’t going like they should have been going so I came out here to White Oak Pastures. I knew nothing. The only thing I knew about chicken was how to fry it. So I did learn a lot once I started on the line. I learned all the different sizes of chickens, how they look, the different breeds, etc. I never knew there were that many breeds of chicken! Then as I got more into it, I started working with the paperwork, I started learning about the HACCP and record keeping and the USDA guidelines. That’s what made it more interesting to me. Then I was like, 'Let me try to do such and such'. So I just tried my way up into it, and I finally got the management position.

At first it was stressful because I was doing a lot of different things all at once. But since I’ve been doing it for awhile, I have everything on track, the way it should be. Now it’s not a problem. I’ve been the manager for the Poultry Plant for two years and am responsible for supervising fifteen people. There are four women and the rest are men in the processing room. When I first started working in there, I thought, 'I’m working with this chicken and I’m going to clean it to the best of my knowledge. I’m also going to clean it as if I am about to buy this chicken for myself, from the store'. I tell my employees to bag the product like something they would buy from the store. Don’t just put anything in the bag. If you go in the store, you’re going to buy the best looking breast there is. If the breast doesn’t look good, we set it aside for pet grind or human consumption grind.

We can slaughter one thousand chickens a day, but we don’t necessarily process that many every day. We slaughter one thousand birds a day if we need to clear out the fields. If we have a limited amount in the field, then we just slaughter by the numbers ordered. I call the poultry field manager and tell him we can do one thousand birds the next day. So he knows to bring one thousand birds. Normally, I look at my orders and think, 'Ok, this is what I need for the next day,' and I call the field manager and tell him what I need. During a week when we slaughter turkeys and ducks, we probably process 3,000-3,500 chickens, plus 500 turkeys, and 250 ducks. But if it’s just chickens all week, we can process 5,000 - 6,000 chickens.

The most satisfying part of my job is knowing that I got all the orders filled and I don’t have anything else to worry with. As long as those orders get filled, I’m satisfied.

The biggest challenge is getting the employees to do what you ask. Sometimes I can tell them to do it one way, and then I see they can’t work it out that way. So I say, 'Let me see how you feel you need to do it'. And then if I see you doing it better than the way I do it, then I say “stick with your way, as long as you are getting the job done, that’s fine. So we work with each other to see what works best individually, because everybody can’t do it like you do. Everybody has their own way of doing things. So I say, let’s do it this way, and then we’ll try your way, and see which way works out the best.

My proudest moment at White Oak Pastures was making the management position. That showed me that they really were paying attention to the work that I was doing, they really were seeing how I was changing and trying to learn.

Describe White Oak Pastures with one word? Indescribable. There’s always something new, something’s growing, or something happening.

The worst part about living in South Georgia is the mosquitos, and the best part is it’s quiet. There is not as much criminal activity and it’s a good place to raise kids. Besides the bugs, everything else is fine.

My favorite White Oak Pastures’ meal to cook is chicken and rice. I bake it or boil it. If I’m doing chicken and rice, I’ll boil the chicken first, cook it down real good and get my chicken broth. I use that same water and put my rice in and let it simmer and cook. That’s the best way to me. When I bake it, I get my Italian dressing, my seasoning salt, and my chicken seasoning and I season my chicken in an empty pan. I pour enough dressing to cover half the chicken, then I cover it with aluminum foil and put it in the oven. I put a little dressing on top of the chicken but pour the other in the pan. When you cover the chicken with aluminum foil, it will make its own broth and will be so tender. I learned from my mama, and I always like to bake with aluminum foil because it keeps all the taste inside. If you put it in the oven without it, it will dry it out. With pork chops, cover them with aluminum foil and cook thirty to forty minutes. Halfway through, stick a fork in the middle to see if it’s done. Sometimes I take the aluminum foil off halfway through cooking and let it brown.

There are a lot of funny things here at White Oak Pastures. One day it was raining and we were going down to the Dining Pavilion, trying to get in, and I slipped all the way down to the ground. I didn’t have nothing but a muddy backside!

If I could switch into a different department for a day? The pet treats seem like they would be interesting. Probably that and the honey bees. I’ve worked in the egg room. I took a rag and wiped the eggs off and put them under the candling machine to make sure they weren’t cracked. Then they were separated them into the different categories: jumbo, medium and small eggs. I’ve done everything in the beef plant, and I’ve worked in the garden. I either pulled weeds or picked vegetables. I’ve helped run the lunch line at the Pavilion and I’ve even thrown hides one time at the old hide barn. I can’t do that, it smells too bad.

Who would I trade roles with on the farm for one day? That is a hard question. I would say Brian, Director of Operations, but his job is hard because he has to deal with everything. I can say Sabrina, Order Manager, because I’ll know her standpoint and what she has to go through to get the orders to me.

My favorite hobby outside of work is playing with my grandchildren and spending time with my kids. I enjoy going places with my kids and grandchildren, and shopping. Every Sunday we go to my mother’s house in Blakely and grill. I have two girls and two boys: Deion is 22, Keshanna is 21, and the twins, Nicholas and Nichole, are 17. Deion works here at White Oak Pastures while Keshanna is in nursing school and is also in the National Guard. Nicholas and Nicole are in the eleventh grade and I have three grandchildren: two boys and one girl.